- Dana Point, CA United States

- +1(949)441-6646

- Dana Point, CA United States

- +1(949)441-6646

- Redwood City, CA United States

- +1(650) 505-0286

We’ve expanded well beyond our flagship technology research to provide senior leaders

Featured Insights

Contact Us

- Redwood City, CA United States

- +1(650) 505-0286

- service@custom-automations.com

Custom Automation

Tailored Automation Equipment for Your Company’s Exact Needs

Space limitations. Extreme operating conditions. Less-than-ideal precision. Ergonomic concerns. Whatever the challenges of your current manufacturing, warehousing or distribution operation, overcome them with custom automation. When your situation demands a one-of-a-kind solution, Bastian Solutions brings you the unparalleled experience and resources to design, fabricate and install it. Let us be your custom manufacturer of innovative solutions for your supply chain.

Engineering and Fabrication

When we engineer or fabricate custom material handling equipment, we keep our eyes on the big picture while also focusing on technical objectives, design reviews, schedule status, financial targets and, above all, customer satisfaction. We fully test the design and operation of your new system in a virtual environment before manufacturing it in the real world, ensuring maximum performance and saving you time and money.

We use three main tools during the engineering and fabrication phase:

Engineering Studies

By investigating your existing processes and exploring different configurations, we’re able to engineer the best custom solution.

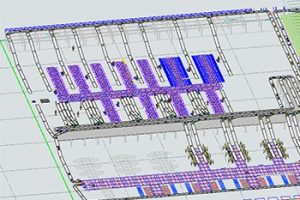

Machine Simulations

We create realistic models of your proposed operation using real-world data, rates, speeds and the logic associated with handling products in order to ensure we are hitting the needed speeds and requirements.

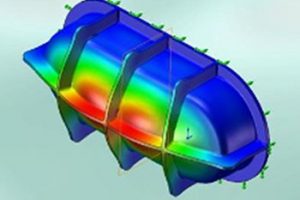

Finite Element Analysis

For projects with large structural loads or precise handling requirements, we can test them virtually for the proper strength, rigidity or flexibility when loaded prior to final execution. This helps to reduce risks and confirm the overall capabilities.